x

C

T

S

E

g

y

p

t

Welcome To CTS Egypt

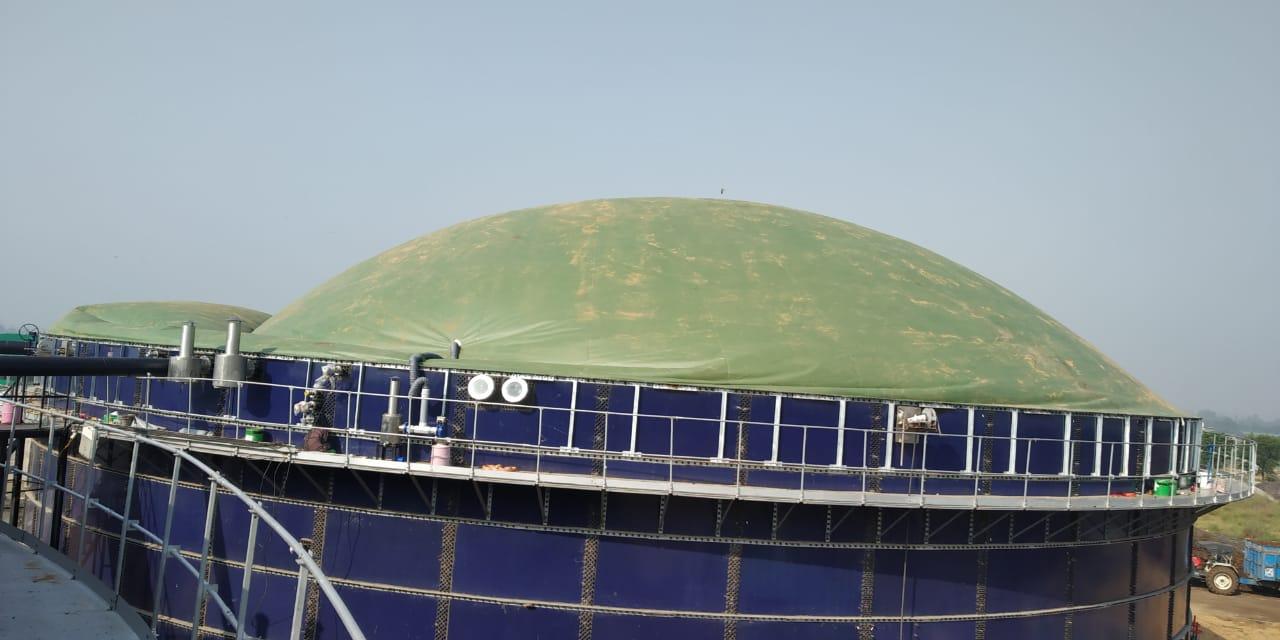

Anaerobic Digestor Tank

Product Details:

The Anaerobic Digester Tank revolutionizes organic waste management by efficiently converting organic materials into biogas and nutrient-rich digestate. Engineered for reliability and sustainability, this tank utilizes anaerobic digestion technology to break down organic matter in the absence of oxygen, generating biogas as a renewable energy source and digestate as a valuable byproduct for agricultural use. With its innovative design and efficient operation, the Anaerobic Digester Tank offers a cost-effective solution for waste treatment and resource recovery, promoting environmental sustainability and renewable energy production in various industries and applications.