x

C

T

S

E

g

y

p

t

Welcome To CTS Egypt

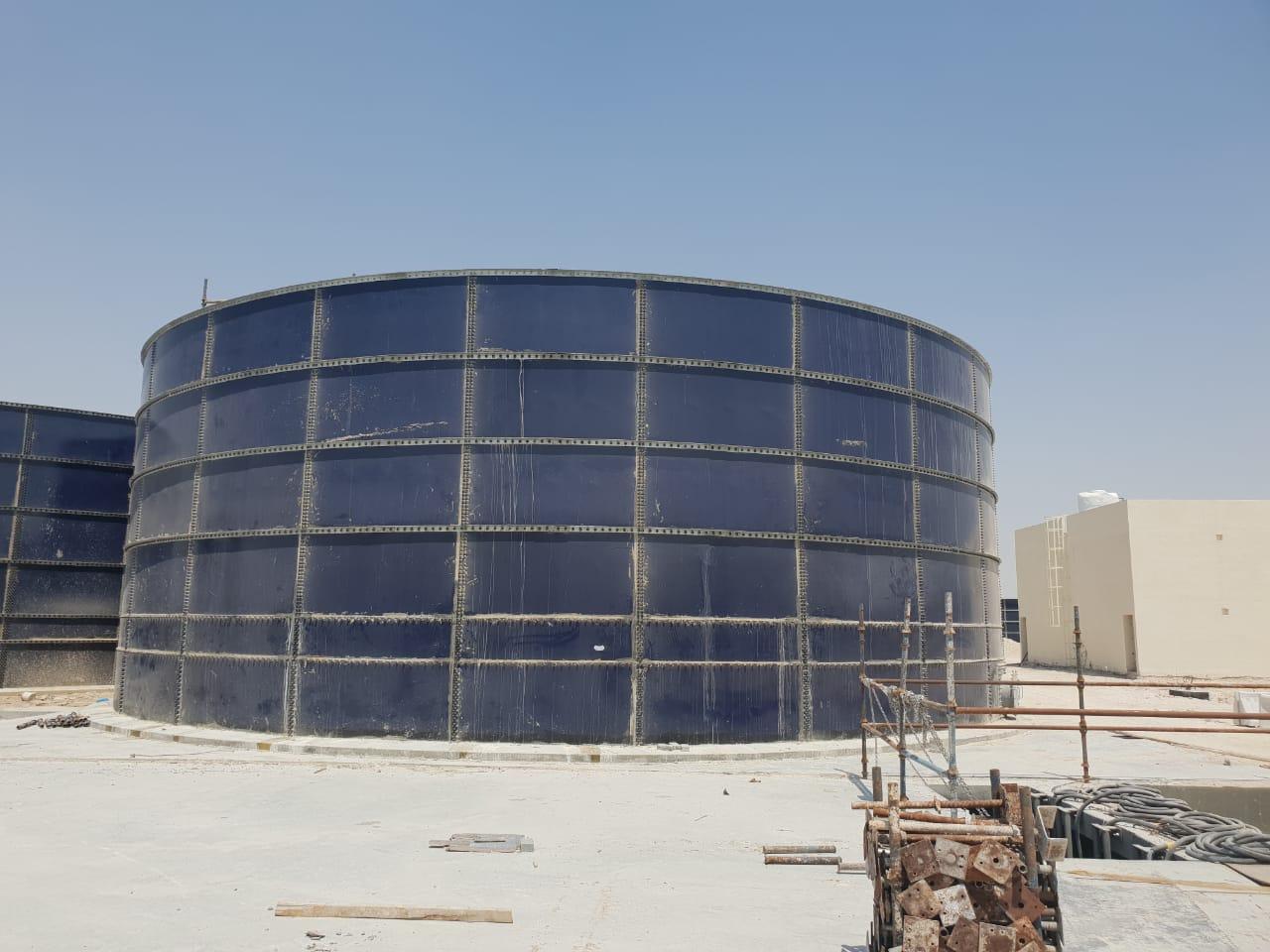

Glass Fused To Steel - GLS/GFS Tank

Product Details:

Optimize liquid storage efficiency and reliability with our Glass Fused to Steel (GLS/GFS) Tanks. Utilizing advanced glass-fused-to-steel technology, these tanks provide durable and corrosion-resistant storage solutions for a wide range of applications, including water storage, wastewater treatment, and industrial processing. With their modular design and customizable options, GLS/GFS Tanks offer versatility and scalability to meet the unique needs of various industries, ensuring reliable and cost-effective liquid storage solutions.